With the rapid development of industrialization, the use of stainless steel chains is becoming more and more important, and on this basis, the requirements for the material and functions of the chain are constantly being improved.Facts have proved that only in accordance with the needs of the market can the chain continue to exist for a longer time.

In the actual application process, in order to be able to use stainless steel chains accurately for a long time, we need to replace stainless steel chains regularly.Even if it is not severely worn, it should be replaced in time. Therefore, the stainless steel chain has a lifespan and cannot be used forever.

Timely replacement of stainless steel chains will greatly help improve its overall strength and rigidity; after the emergence of programmable controllers and computers, the development of stainless steel chains will have more momentum.When the electrical control system of the stainless steel chain is equipped with high-precision, high-sensitivity, high-reliability speed control, signal acquisition, signal transmission, and logic execution components, then its electrical control level is bound to be greatly improved.

In this way, even some complex automated conveyor lines with logic network functions can be achieved through the stainless steel chain control level, thus bringing users a more convenient production mode.Among the stainless steel chains, non-standard chains are mainly made for users who are not suitable for ordinary specifications, but in terms of quality, they are also made completely according to the standards of specification chains.

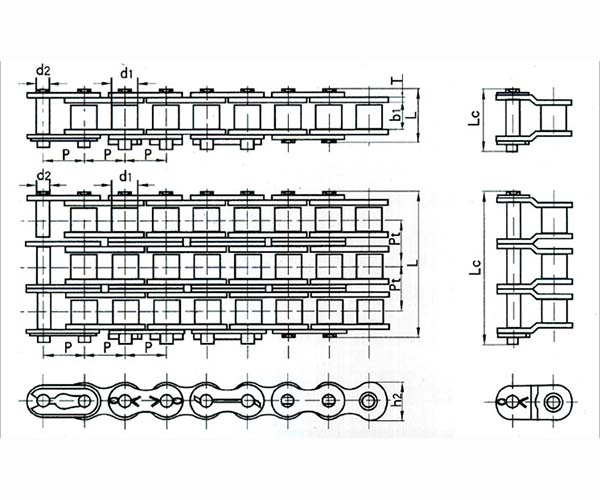

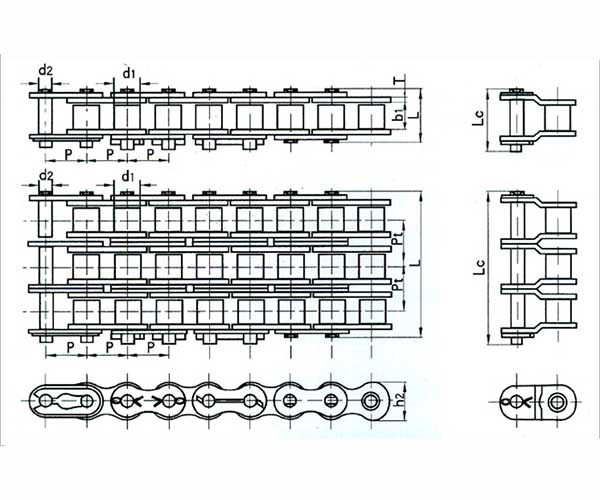

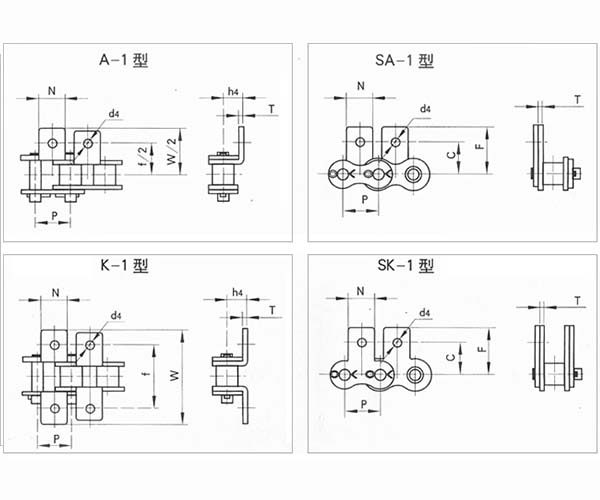

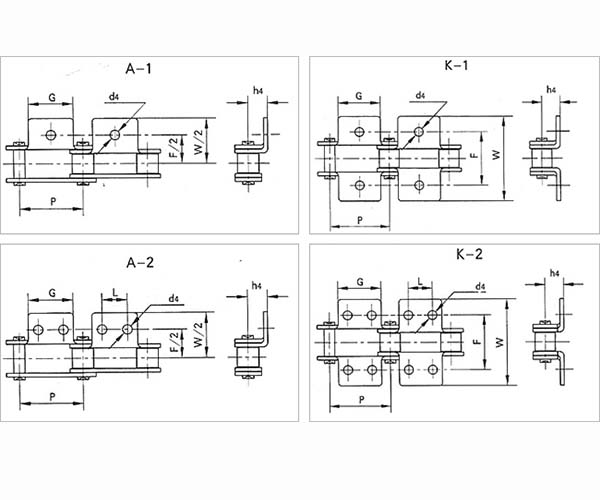

The non-standard stainless steel chain uses the chain as the traction and carrier to transport materials. It can use ordinary sleeve roller conveyor chains or various other special chains. The key depends on the actual needs of users.In terms of its production, it adopts automatic multiple blanking high-speed punching machine, automatic heat treatment mesh belt production line, numerical control lathe, wire cutting program control and other equipment.

All in all, the non-standard stainless steel chain from the selection of raw materials, to cold rolling, punching, heat treatment, and automatic assembly are all completed at one time, which not only makes the production system efficient, flexible and stable, but also has better product quality.